In the foundry industry, post-treatment processes such as gating, riser, and runner removal, as well as surface finishing operations including grinding, deburring, and sandblasting, are critical to ensuring product quality and production efficiency. Traditional manual operations often result in low productivity, inconsistent results, and elevated safety risks. By integrating automation into post-treatment operations, foundries can significantly improve throughput, maintain consistent part quality, and reduce worker exposure to hazardous environments. DS Technology provides advanced automation solutions, including robotic systems for cutting, abrasive blasting, and surface finishing, helping manufacturers implement smart production and enhance their market competitiveness.

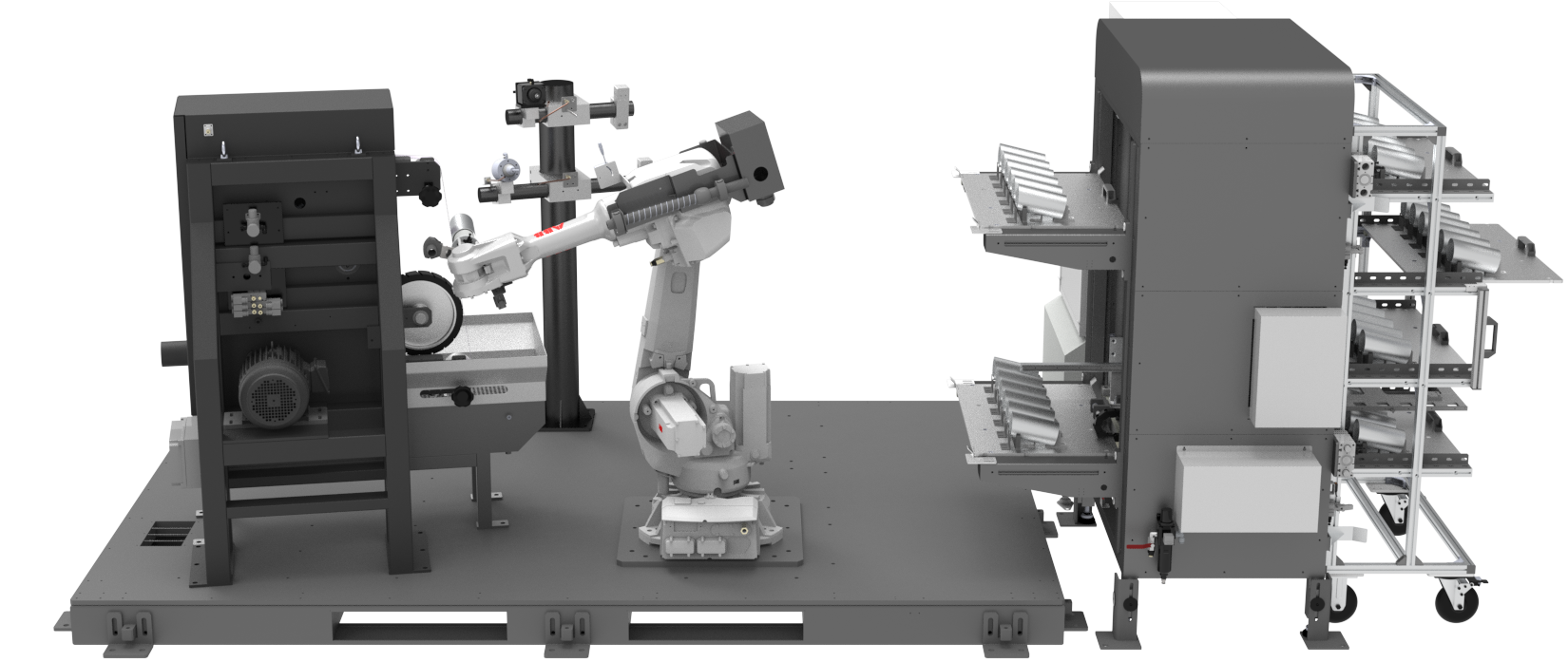

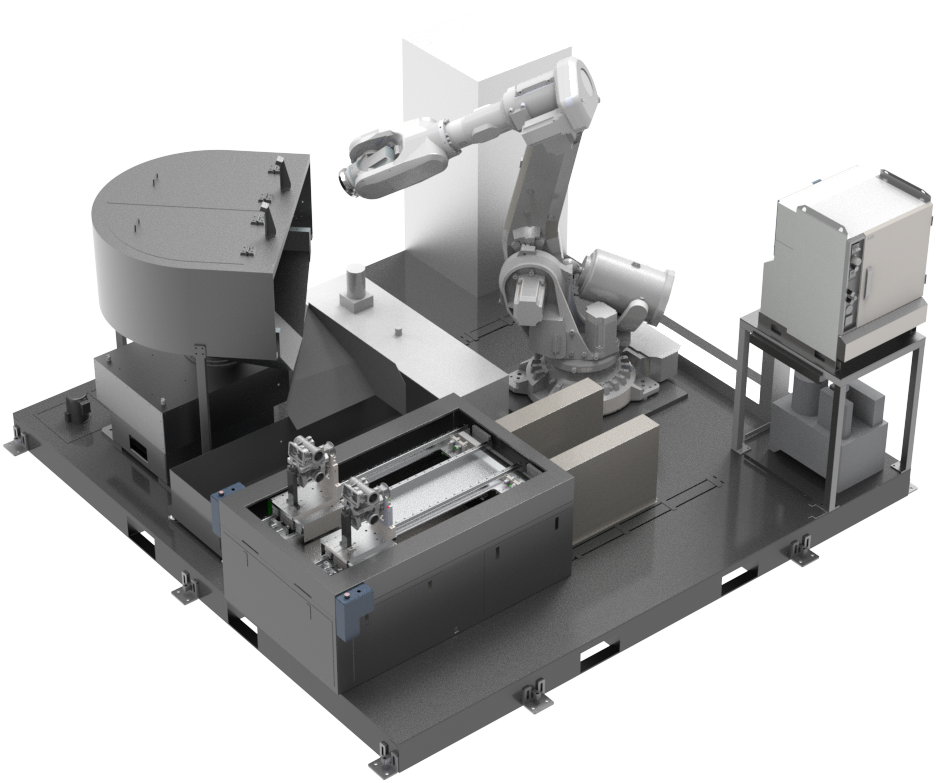

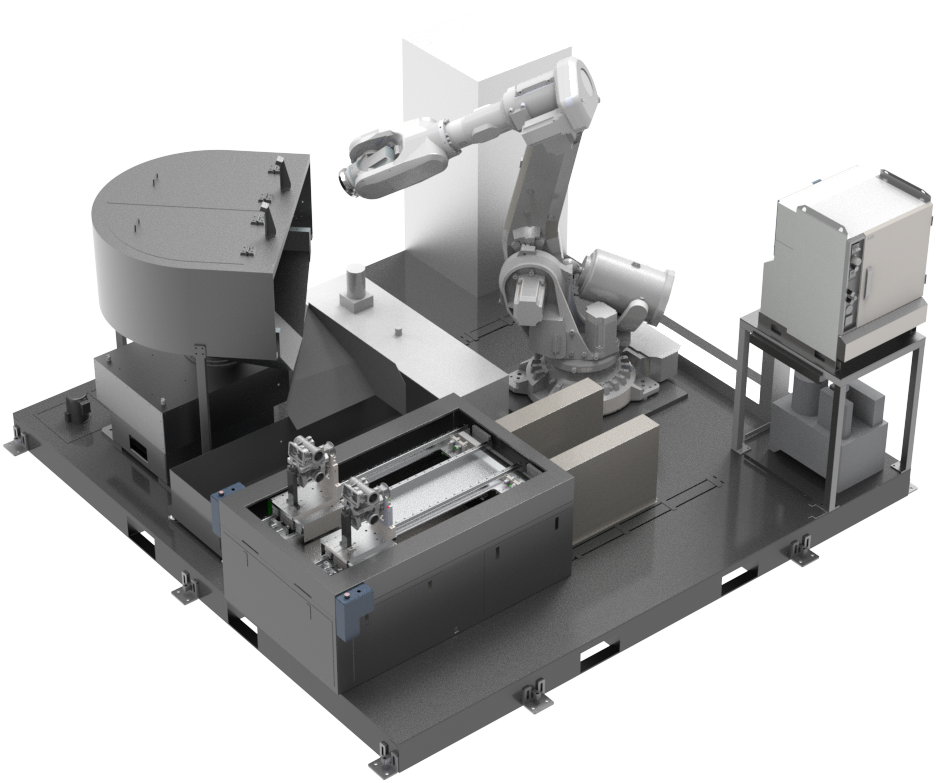

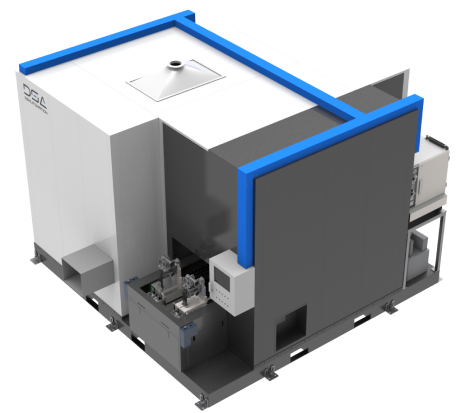

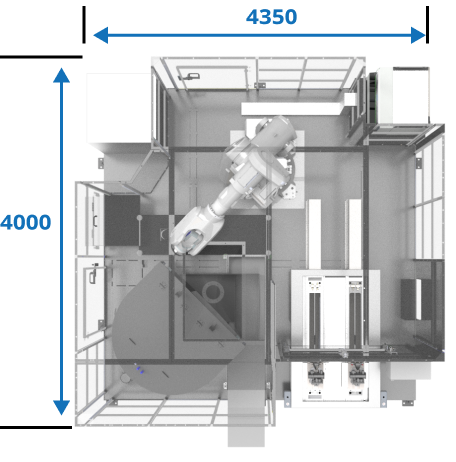

DS Technology offers two modular robotic surface finishing solutions tailored for different production needs in the foundry industry. The RTH-2TP Dual-Station Robotic Tool-Handheld Surface Finishing System features a robot that holds and manipulates a handheld grinding tool. This configuration provides high flexibility and is ideal for castings with complex geometries or varying part sizes. The RWH-3DF Robotic Workpiece-Handheld Surface Finishing System utilizes a robot to grip the workpiece and present it to a fixed abrasive tool. This setup ensures consistent contact angles and finishing quality, making it well-suited for compact or investment castings. Both systems are modular and engineered to meet a wide range of grinding and deburring requirements across different casting materials and shapes.

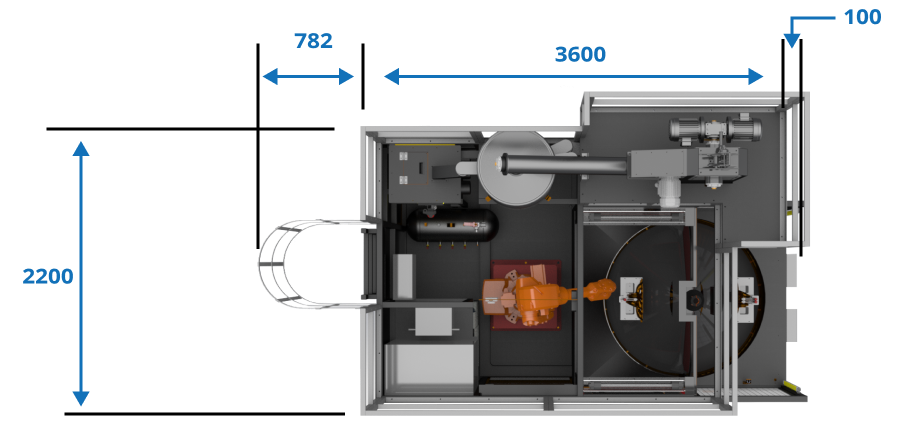

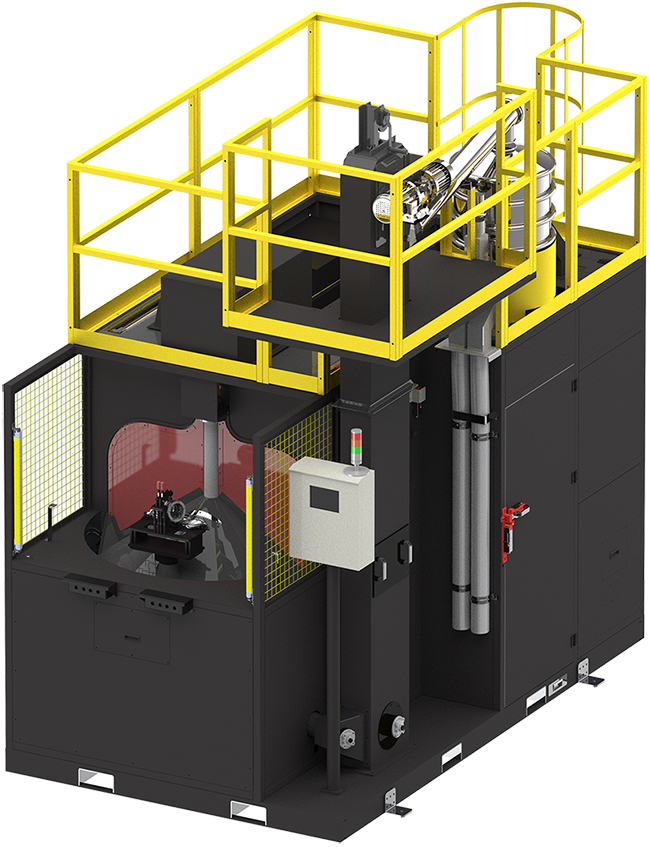

This system is specifically designed for automated cutting of gating, risers, and runners in castings, integrating intelligent monitoring and high-durability diamond cutting blades to ensure precise and efficient cutting performance. It effectively reduces consumable usage and production costs while enhancing operational safety. Utilizing robotic automation, the system achieves consistent cutting results and is applicable to steel, cast iron, aluminum alloys, and stainless steel, helping manufacturers improve production efficiency and competitiveness.

Consistent Cutting Quality, Seamlessly Integrating Automation

Reduced Labor and Maintenance Costs

Increased Production Efficiency

Reduced Abrasive Material Waste

Enhanced Safety

Fully Automated Operation

DS Cloud AI Smart Monitoring System

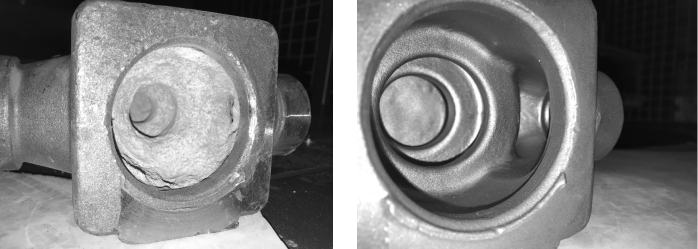

Before Cleaning

After Cleaning

Consistency and Uniformity

Improved Working Environment with Reduced Labor Costs

Reduced Sand Consumption Waste

Enhanced Workpiece Quality

Offline Programming for High-Efficiency Integration

DS Cloud AI Smart Monitoring System

Main Applications